Wiring Diagram Wiper Motor is a crucial tool for understanding the electrical system of a vehicle’s wiper motor. By providing a visual representation of the wiring connections and components involved in the wiper motor system, it helps mechanics and DIY enthusiasts troubleshoot issues and make necessary repairs.

Why are Wiring Diagram Wiper Motor essential?

Wiring Diagram Wiper Motor are essential for several reasons:

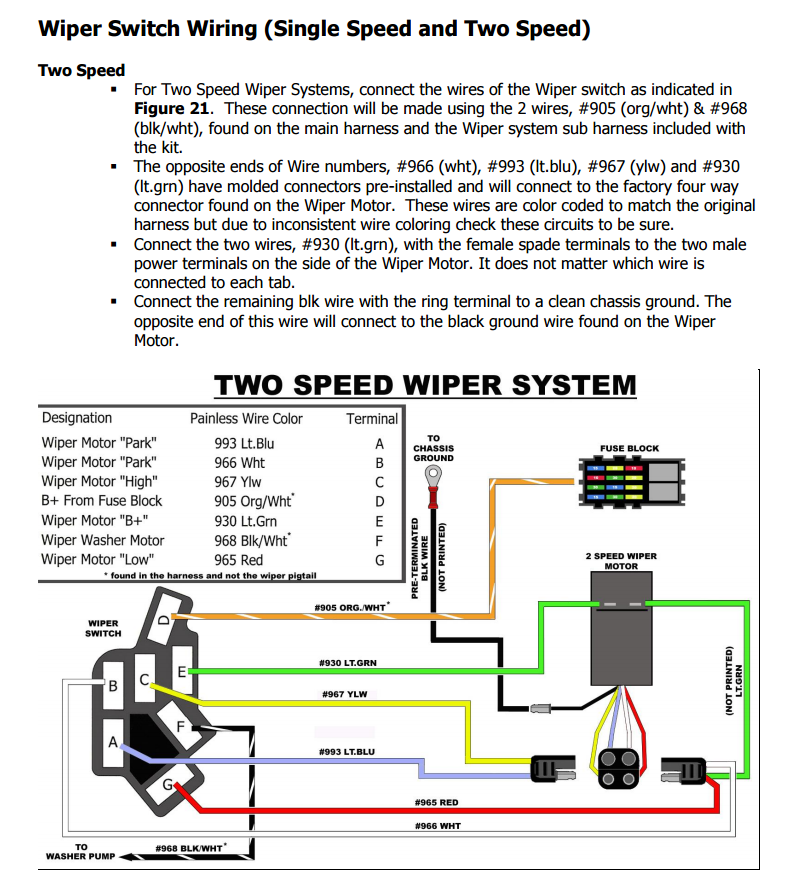

- They provide a detailed illustration of the electrical components and connections in the wiper motor system.

- They help identify potential issues or faults in the wiring that may be causing wiper motor malfunctions.

- They serve as a guide for properly installing or repairing the wiper motor system.

How to read and interpret Wiring Diagram Wiper Motor effectively

Reading and interpreting Wiring Diagram Wiper Motor effectively requires a basic understanding of electrical symbols and circuit diagrams. Here are some tips to help you:

- Familiarize yourself with common electrical symbols used in wiring diagrams.

- Follow the flow of the wiring diagram to understand the sequence of electrical connections.

- Pay attention to color codes and labels to identify different wires and components.

Using Wiring Diagram Wiper Motor for troubleshooting electrical problems

Wiring Diagram Wiper Motor are invaluable tools for troubleshooting electrical problems in the wiper motor system. Here’s how you can use them effectively:

- Identify the specific circuit or component that is causing the issue by tracing the wiring connections in the diagram.

- Check for continuity, voltage, or resistance at different points in the circuit to pinpoint the source of the problem.

- Refer to the wiring diagram to determine the correct wiring connections and ensure proper installation or repair.

Importance of safety when working with electrical systems

When working with electrical systems and using wiring diagrams, it is crucial to prioritize safety to avoid accidents or injuries. Here are some safety tips and best practices to follow:

- Disconnect the vehicle’s battery before working on any electrical components to prevent electrical shock.

- Avoid working on electrical systems in wet or damp conditions to reduce the risk of short circuits.

- Use insulated tools and wear appropriate protective gear, such as gloves and goggles, when handling electrical components.

- Follow manufacturer’s instructions and guidelines when using wiring diagrams to ensure proper handling and installation of electrical systems.

Wiring Diagram Wiper Motor

Gm Wiper Motor Wiring Diagram: Understanding The Basics – Moo Wiring

How To Wire A Windshield Wiper Motor

C3 Corvette Wiper Motor Wiring Diagram

Wiring Diagram Wiper Motor

1954 Ford Truck Wiper Motor Wiring

Wiper motor wiring diagram chevrolet

4 wire wiper motor wiring diagram