Understanding how to properly read and interpret a Loop Detector Wiring Diagram is essential for any skilled mechanic or electrician. These diagrams provide a visual representation of the electrical connections within a loop detector system, allowing professionals to troubleshoot and repair any issues that may arise. In this comprehensive guide, we will explore the importance of Loop Detector Wiring Diagrams and provide guidance on how to effectively utilize them.

Importance of Loop Detector Wiring Diagrams

Loop Detector Wiring Diagrams are crucial for several reasons:

- They provide a visual representation of the electrical connections within a loop detector system.

- They help professionals understand the layout of the wiring and components.

- They assist in troubleshooting electrical problems quickly and efficiently.

Reading and Interpreting Loop Detector Wiring Diagrams

When reading a Loop Detector Wiring Diagram, it is essential to:

- Identify the components and their corresponding symbols.

- Follow the flow of the electrical connections from one component to another.

- Understand the color codes and labeling used in the diagram.

Using Loop Detector Wiring Diagrams for Troubleshooting

Loop Detector Wiring Diagrams are invaluable tools for troubleshooting electrical problems. By following the electrical connections in the diagram, professionals can:

- Locate faulty components or connections.

- Identify potential short circuits or open circuits.

- Verify proper voltage and current flow within the system.

Safety Tips for Working with Electrical Systems

When working with electrical systems and using wiring diagrams, it is crucial to prioritize safety. Here are some important safety tips and best practices to follow:

- Always turn off the power supply before working on any electrical system.

- Use insulated tools to prevent electrical shocks.

- Wear appropriate personal protective equipment, such as gloves and goggles.

- Double-check all connections before restoring power to the system.

Loop Detector Wiring Diagram

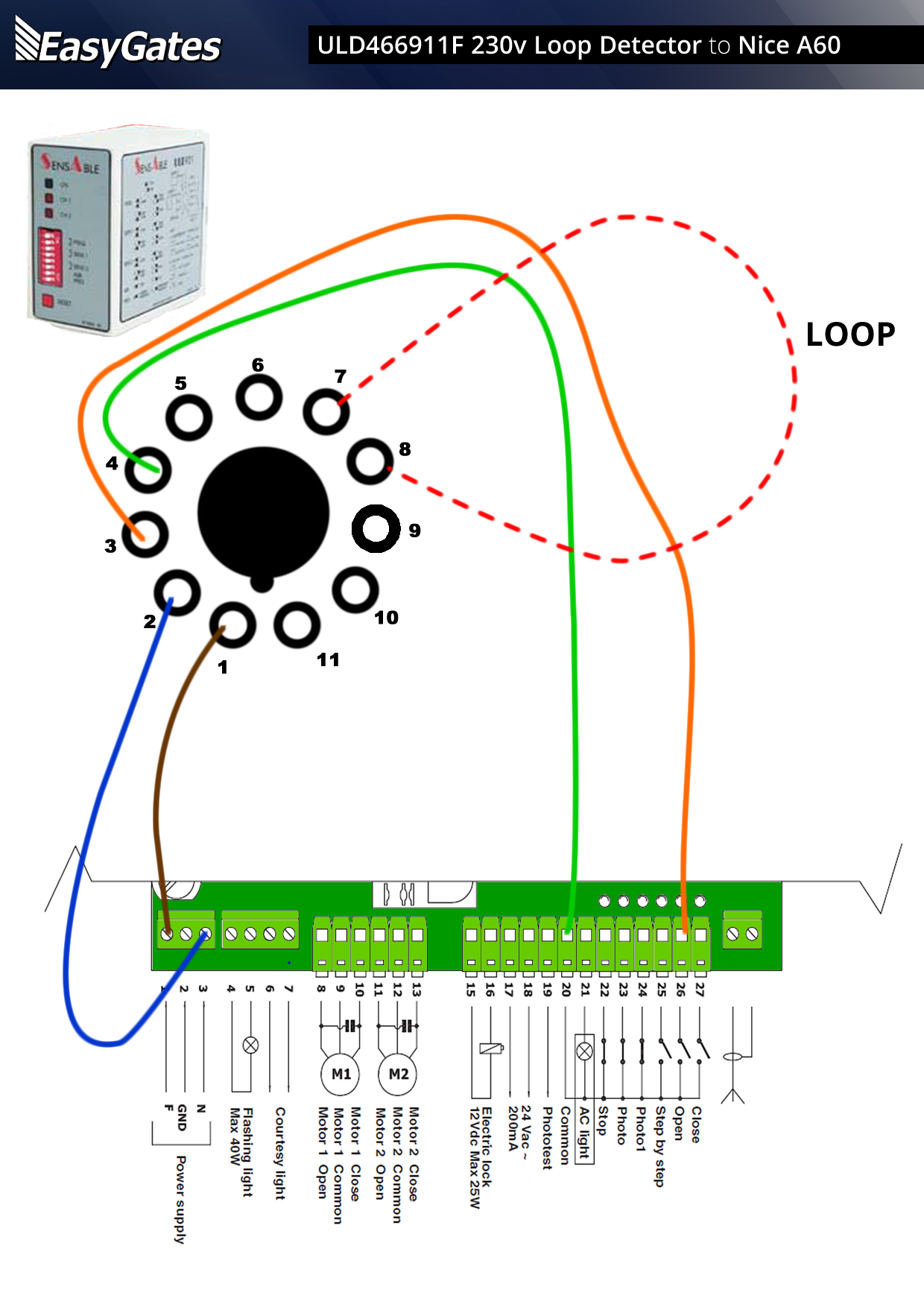

230 volt Loop Detector to Nice A60 Control Board

Vehicle Loop Detector Wiring Diagram – Wiring Diagram

Vehicle Loop Detector Wire 305m For Parking Barrier Gate Arm Closing

Vehicle Loop Detectors – JUTAI Brand Single/Dual Channel – JUTAI

Nice Inductive Vehicle Loop Detector For Traffic Access Control System

29+ loop detector wiring diagram – GerardKamile

Vehicle Loop Detector Wiring Diagram – Wiring Diagram

Loop Wiring Diagram Instrumentation – inspireops