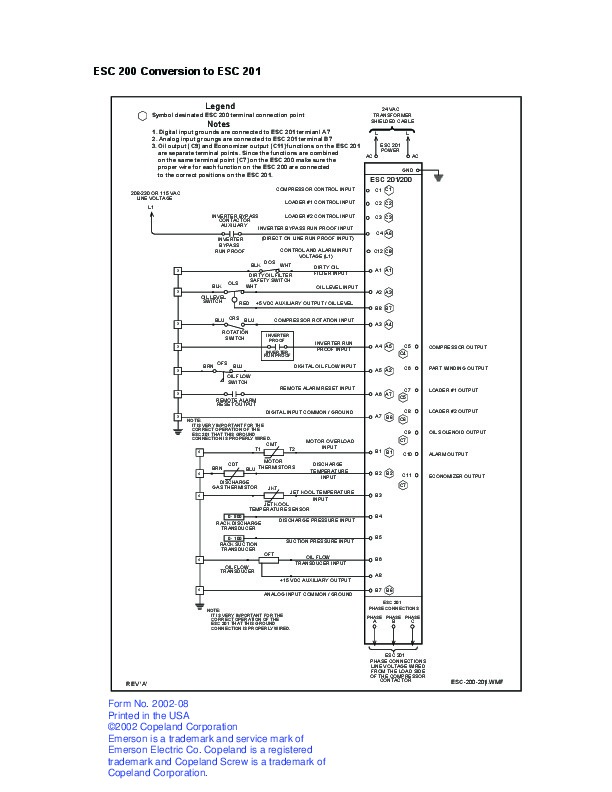

When working with HVAC systems, understanding the Copeland Compressor Wiring Diagram is crucial for proper installation and maintenance. The wiring diagram provides a visual representation of the electrical connections within the compressor, helping technicians to troubleshoot issues and ensure the system operates smoothly.

Why Copeland Compressor Wiring Diagram are essential

- Ensure correct installation of the compressor

- Help troubleshoot electrical issues

- Prevent damage to the compressor and other components

- Ensure safety during maintenance and repairs

How to read and interpret Copeland Compressor Wiring Diagram effectively

Reading and interpreting a Copeland Compressor Wiring Diagram may seem daunting at first, but with practice, it becomes easier. Here are some tips to help you navigate the diagram:

- Identify the components: Understand the symbols and labels used in the diagram to locate the different components of the compressor.

- Follow the flow: Trace the flow of electricity from the power source to the compressor and other parts of the system.

- Check for connections: Ensure all connections are secure and properly aligned according to the diagram.

How Copeland Compressor Wiring Diagram are used for troubleshooting electrical problems

When facing electrical issues with the compressor, the wiring diagram is a valuable tool for troubleshooting. Here’s how you can use the diagram effectively:

- Identify the problem area: Locate the section of the diagram related to the malfunctioning component to pinpoint the issue.

- Check for continuity: Use a multimeter to test the continuity of the electrical connections and identify any faults.

- Refer to the diagram: Compare the actual wiring with the diagram to see if there are any discrepancies or errors in the connections.

Importance of safety when working with electrical systems

When working with electrical systems and wiring diagrams, safety should always be a top priority. Here are some safety tips and best practices to follow:

- Disconnect power: Always disconnect the power source before working on the compressor to prevent electrical shocks.

- Use insulated tools: When handling electrical components, use insulated tools to avoid accidental contact with live wires.

- Wear protective gear: Wear gloves and safety goggles to protect yourself from electrical hazards and sharp edges.

- Refer to manufacturer guidelines: Follow the manufacturer’s instructions and guidelines for working on the compressor to ensure safety and proper operation.

Copeland Compressor Wiring Diagram

Copeland Hermetic Compressor Wiring Diagram – Wiring Diagram

Copeland Scroll Compressor Wiring Diagram

Wiring a Kriwan Module to a Copeland Compressor – YouTube

Copeland Scroll Compressor Single Phase Wiring Diagram – Circuit Diagram

Copeland Compressor Wiring Schematic Vw T5 Light Switch Diagram

Emerson Copeland Screw Compressors Manual

Jean Scheme: Wiring Diagram Hermetic Compressor / Copeland Compressor

The Ultimate Guide to Understanding Copeland Compressor Wiring Diagrams