Boat Kill Switch Wiring Diagrams are essential tools for boat owners and mechanics alike to understand the electrical systems on their boats. These diagrams provide a visual representation of the wiring connections and components involved in the kill switch system, which is crucial for ensuring the safety and proper functioning of the boat.

Why Boat Kill Switch Wiring Diagrams are Essential

Boat kill switch wiring diagrams are essential for the following reasons:

- They help in understanding the electrical connections and components of the kill switch system.

- They aid in troubleshooting electrical problems and identifying faulty components.

- They ensure proper installation and maintenance of the kill switch system.

How to Read and Interpret Boat Kill Switch Wiring Diagrams

Reading and interpreting boat kill switch wiring diagrams can be daunting for those unfamiliar with electrical systems. Here are some tips to help you understand them effectively:

- Start by familiarizing yourself with the symbols and abbreviations used in the diagram.

- Follow the flow of the wiring connections from the power source to the kill switch and other components.

- Pay attention to the color codes of the wires, as they indicate their function and connectivity.

Using Boat Kill Switch Wiring Diagrams for Troubleshooting

Boat kill switch wiring diagrams are invaluable when it comes to troubleshooting electrical problems on a boat. Here’s how you can use them effectively:

- Identify the specific circuit or component that is malfunctioning by referring to the wiring diagram.

- Trace the wiring connections to check for loose connections, damaged wires, or faulty components.

- Compare the actual wiring on the boat to the diagram to ensure they match up correctly.

Importance of Safety

When working with boat kill switch wiring diagrams or any electrical systems, safety should always be the top priority. Here are some safety tips and best practices to keep in mind:

- Always disconnect the power source before working on any electrical system to prevent electric shock.

- Use insulated tools and wear protective gear, such as gloves and goggles, when handling electrical components.

- Double-check your work and ensure all connections are secure before re-energizing the system.

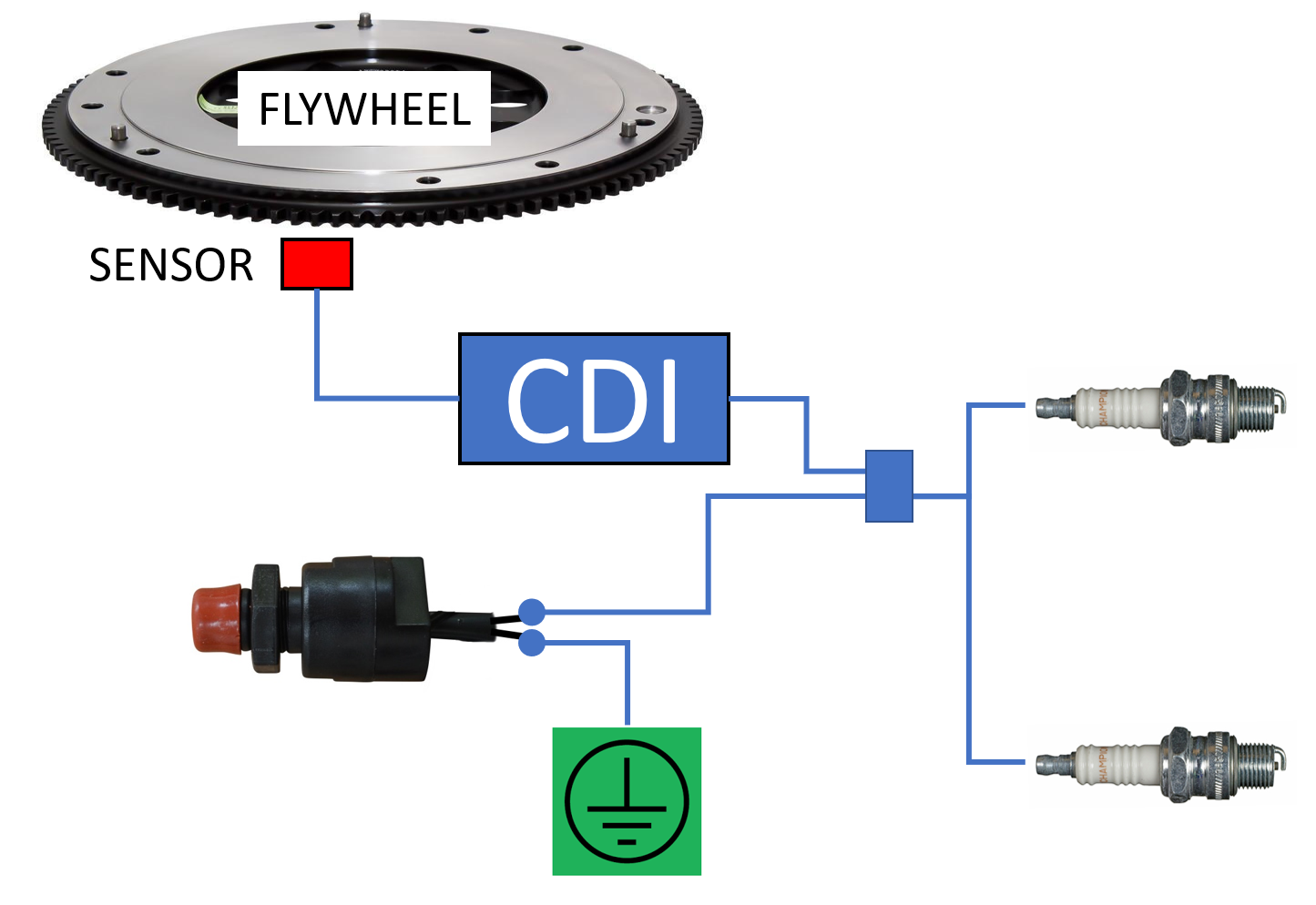

Boat Kill Switch Wiring Diagram

How To Fit A Kill-Switch | Boat Fittings

How To Fit A Kill-Switch | Boat Fittings

How to Install a Killswitch on a Boat: Only 4 Steps

How to Install a kill switch/lanyard? – Offshoreonly.com

Wiring Diagram For Seadog Safety Kill Switch

How to Properly Wire a Marine Ignition Switch: Step-by-Step Wiring Diagram

Boat Kill Switch Diagram

How to Install and Wire a Boat Kill Switch: A Step-by-Step Guide