When working on a classic car like the 1965 Mustang, having access to the ignition switch wiring diagram is crucial. This diagram provides a detailed layout of the electrical connections for the ignition system, allowing mechanics to troubleshoot issues and make necessary repairs. Understanding how to read and interpret the wiring diagram is essential for any restoration project or repair job.

Why are 1965 Mustang Ignition Switch Wiring Diagrams Essential?

The ignition switch wiring diagram for a 1965 Mustang is essential for several reasons:

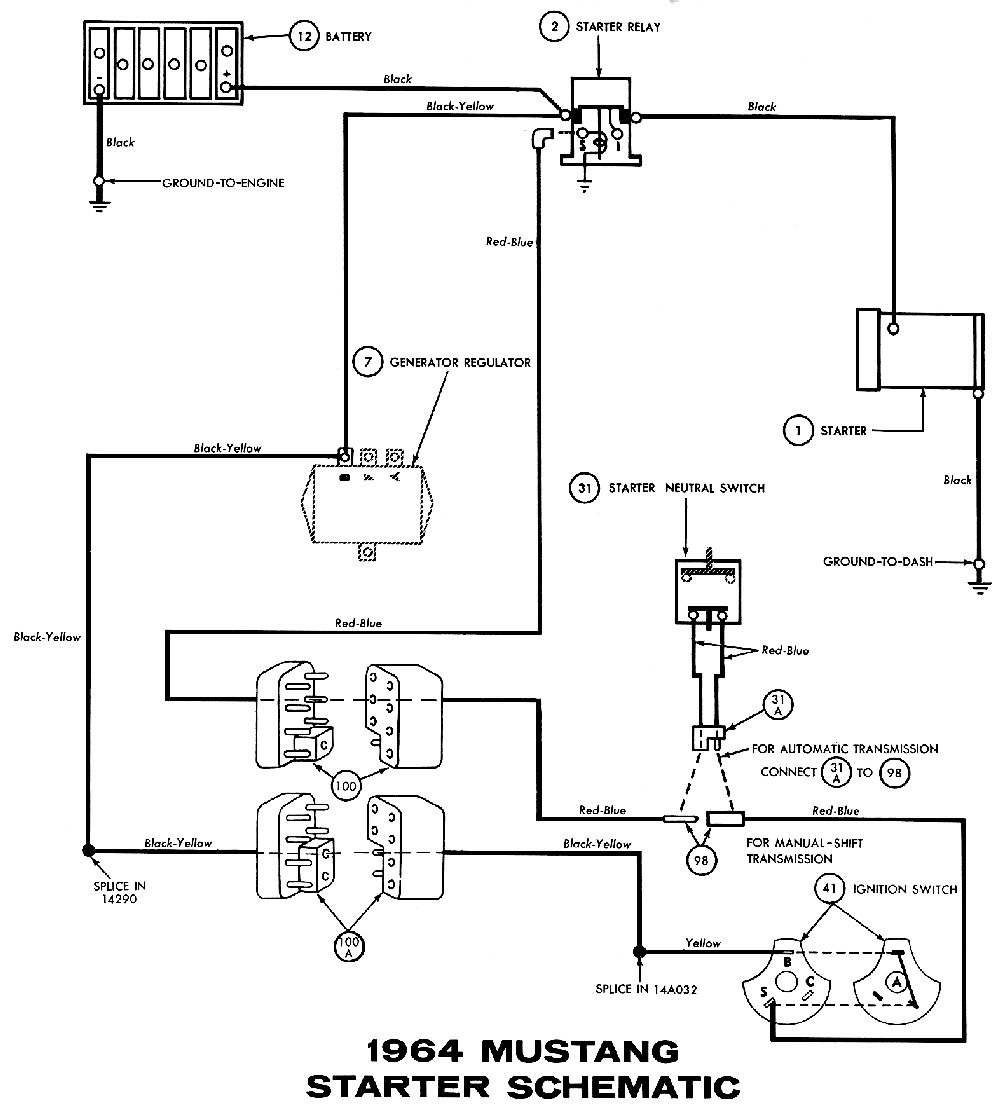

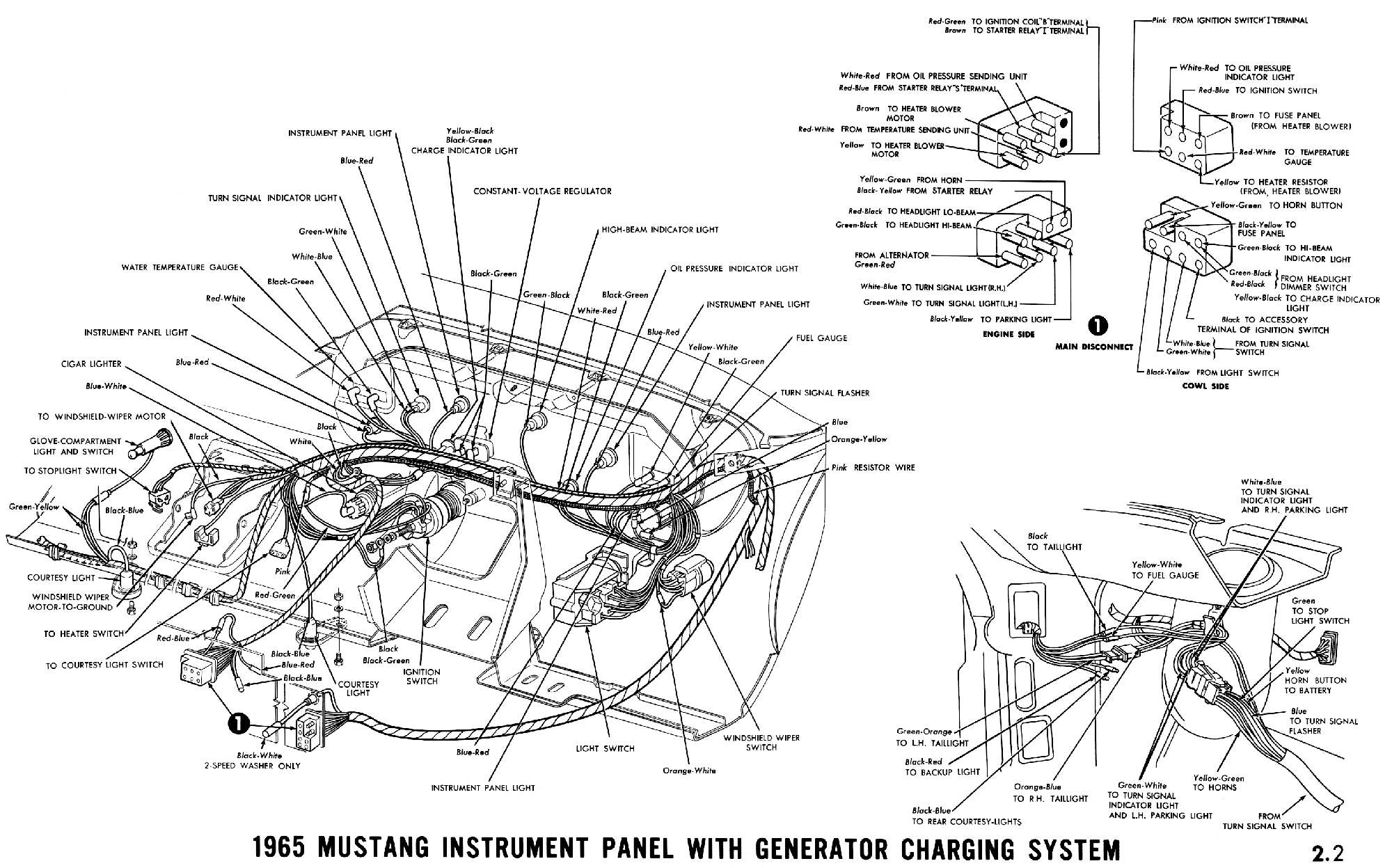

- It provides a visual representation of the electrical connections in the ignition system.

- It helps identify the components involved in the ignition system.

- It guides mechanics in diagnosing and fixing electrical issues.

How to Read and Interpret 1965 Mustang Ignition Switch Wiring Diagrams

Reading and interpreting the wiring diagram for a 1965 Mustang ignition switch may seem daunting at first, but with some guidance, it can be a valuable tool for any mechanic. Here are some tips to help:

- Start by familiarizing yourself with the symbols and color codes used in the diagram.

- Follow the flow of the diagram from the ignition switch to the various components.

- Pay attention to the connections and wiring paths to understand how the system works.

Using 1965 Mustang Ignition Switch Wiring Diagrams for Troubleshooting

When faced with electrical problems in a 1965 Mustang, the ignition switch wiring diagram can be a lifesaver. Here’s how you can use it for troubleshooting:

- Identify the specific circuit or component that is causing the issue.

- Trace the wiring connections to locate any faulty connections or components.

- Refer to the diagram to understand how the system should work and compare it to the actual setup.

Importance of Safety When Working with Electrical Systems

Working with electrical systems, including using wiring diagrams, requires caution and adherence to safety practices. Here are some important safety tips to keep in mind:

- Always disconnect the battery before working on any electrical components.

- Use insulated tools to prevent electrical shocks.

- Avoid working on electrical systems in wet or damp conditions.

- Double-check all connections and wiring before reassembling components.

1965 Mustang Ignition Switch Wiring Diagram

1965 Mustang Ignition Switch Wiring Diagram Download – Wiring Diagram

Basic Ignition Wiring Diagram 1965 Mustang

1965 Ford Mustang Ignition Switch

1965 Mustang Ignition Switch Wiring Diagram – Wiring Diagram

1965 Mustang Wiring Diagrams | Average Joe Restoration

1965 Mustang Ignition Switch Wiring – Zoya Perry

Mustang Scott Drake Ignition Switch Assembly (1965-1966) Installation

1965 Mustang Ignition Switch Wiring Diagram – inspireium